Designing entertainment venues—whether they are arenas, theatres, research halls or also concert halls—comes with unique acoustic challenges.

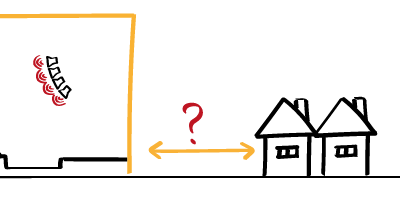

High noise levels, especially at low frequencies, can easily reach nearby homes or sensitive areas, creating problems in urban settings.

So, how do you effectively manage noise while meeting your sustainability goals and staying on budget?

In this post, you will learn about some key acoustic challenges when building entertainement venues using mass timber (or ‘just’ timber).

But it’s not all challenges—there are great opportunities too!

You will also discover how good planning methods, modular construction, and other low-carbon solutions can help you create acoustically optimised venues that are sustainable and financially optimised.

Enjoy the read!

Need an Acoustic Design Audit?

You are at the beginning or concept design stage of a timber project and need a direction for the acoustic design?

Atelier Crescendo offer a bite-sized, zero-cost service including:

📞 a 30-minute call to do through the project and proposals

🪵🔍 a quick review of the timber structure

🪵 assessment of up to 3 wall build-ups

🪵 assessment of up to 3 floor build-ups

✍️ a concise 1–2-page design note to summarise our recommendations

We will do it wherever your project is.

Acoustic design of entertainement venues into context

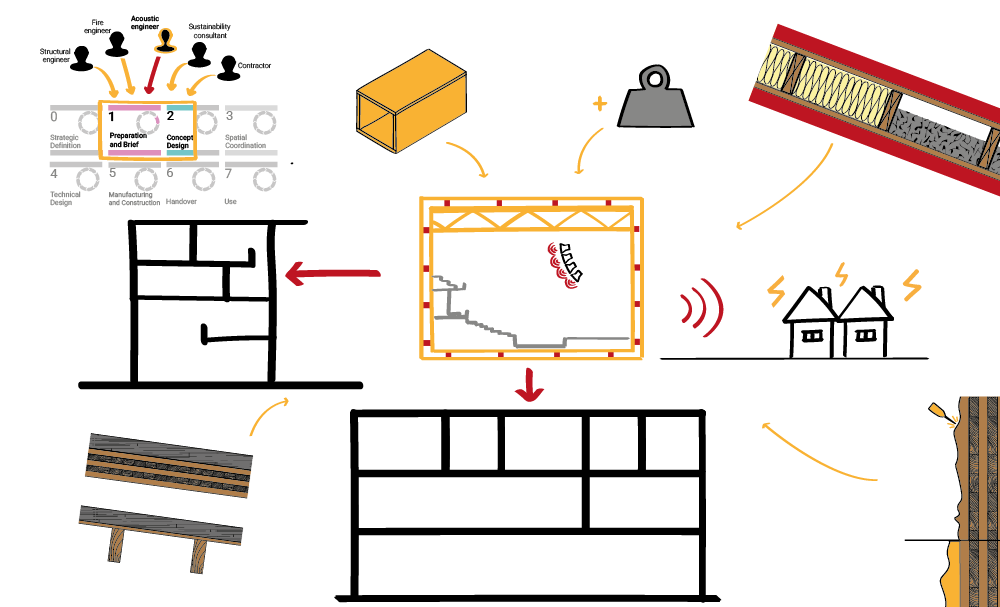

Managing high noise levels in urban entertainement venues

Venues like arenas and music halls often have powerful sound systems that generate high sound levels, especially at low frequencies. (if you need a refresher on the fundamentals of acoustics, including frequencies, read this post)

Low-frequency sounds travel more easily through walls, windows, floors, and ceilings than mid or high frequencies.

This makes controlling low-frequency sound leakage more difficult, especially when the venue is near residential or sensitive areas.

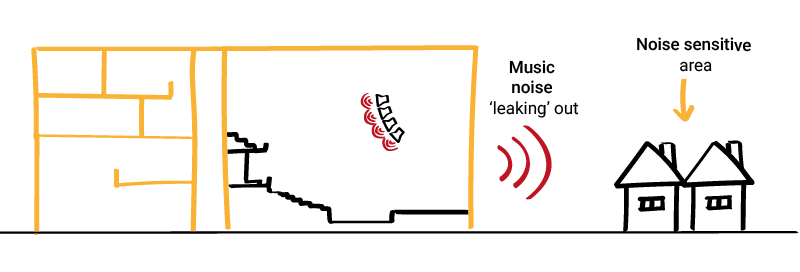

Enclose entertainement venues to contain noise

You can sometimes manage noise directly at the source by:

- limiting the sound levels;

- or modifying the equipment.

But the most effective approach is to fully enclose the venue.

A well-insulated enclosure, including walls, ceilings, and roofs, effectively contains noise inside your venue.

However, this solution can be expensive, and the level of enclosure required depend on several factors.

Factors influencing the noise control: sensitivity, distance, and frequency

The level of noise control you need depends on several factors.

- how sensitive the surrounding areas are;

how far away they are;

how often and for how long the venue hosts loud events.

These considerations will guide your decisions on the level of ‘soundproofing‘ required.

Staying on budget

Not only does mass timber look amazing when you expose it, but it can also help meet sustainability goals like low embodied carbon and net-zero targets.

However, if we approach the design and construction in a traditional way (i.e. designing with no contractors involved), these venues are more likely to become too expensive and financially unfeasible. And sometimes, because of the acoustic design and treatments.

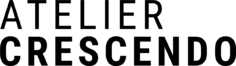

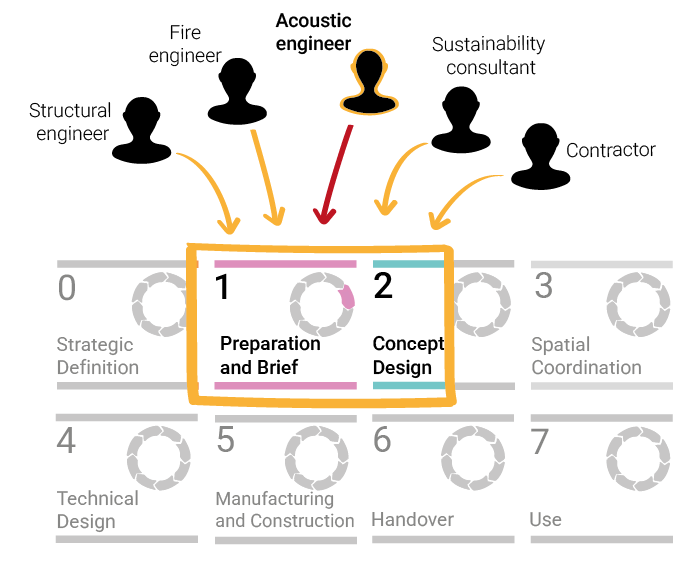

This is why it’s essential to engage the right consultants—and the contractor—as early as possible, especially those with expertise in modern prefabricated and modular construction techniques.

Acoustic Challenge: Dense box or 'Box-in-box'

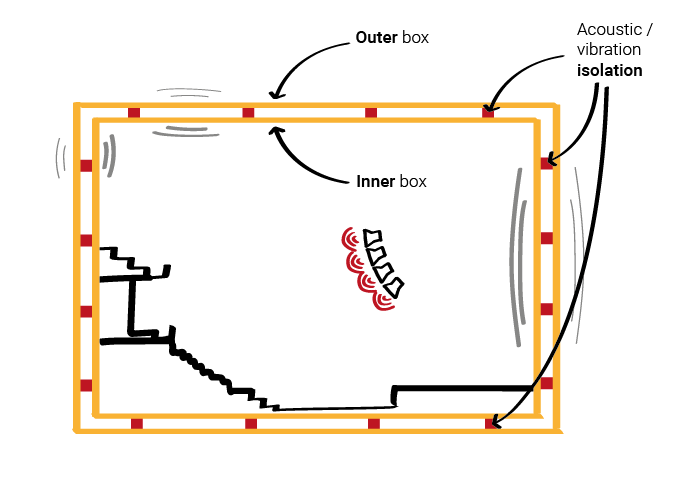

The required level of sound control typically determines the construction approach for the enclosure of your venue.

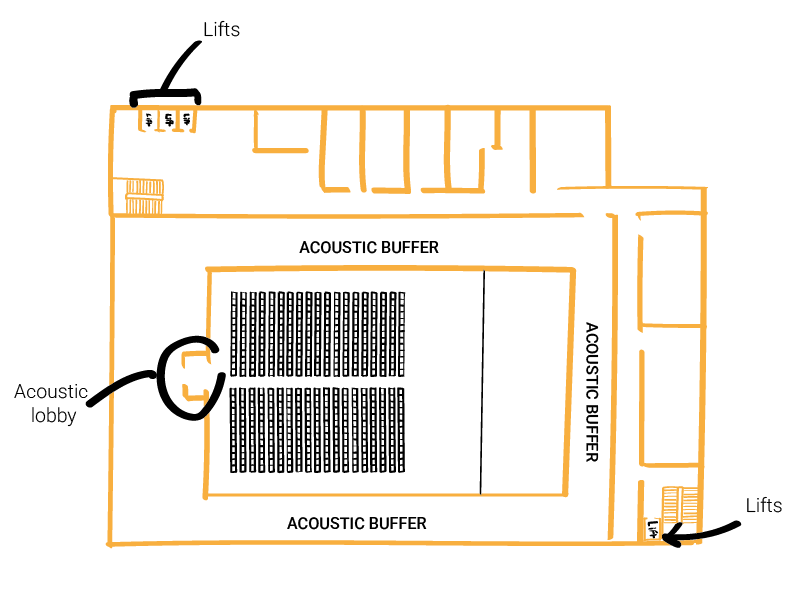

For venues near noise-sensitive areas, the design usually ranges from:

- a dense, well-insulated box, featuring heavy roofs, facades, and possibly floors;

- to a full box-in-box system.

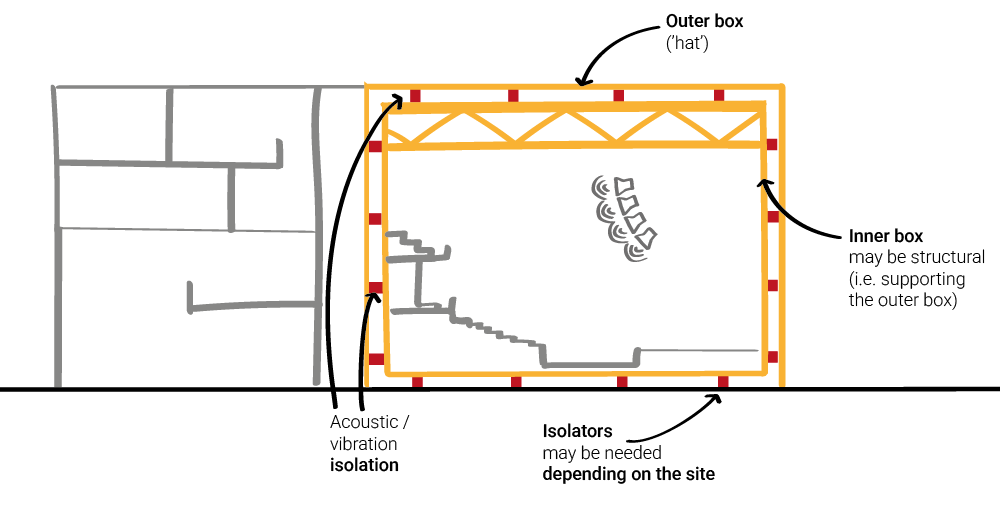

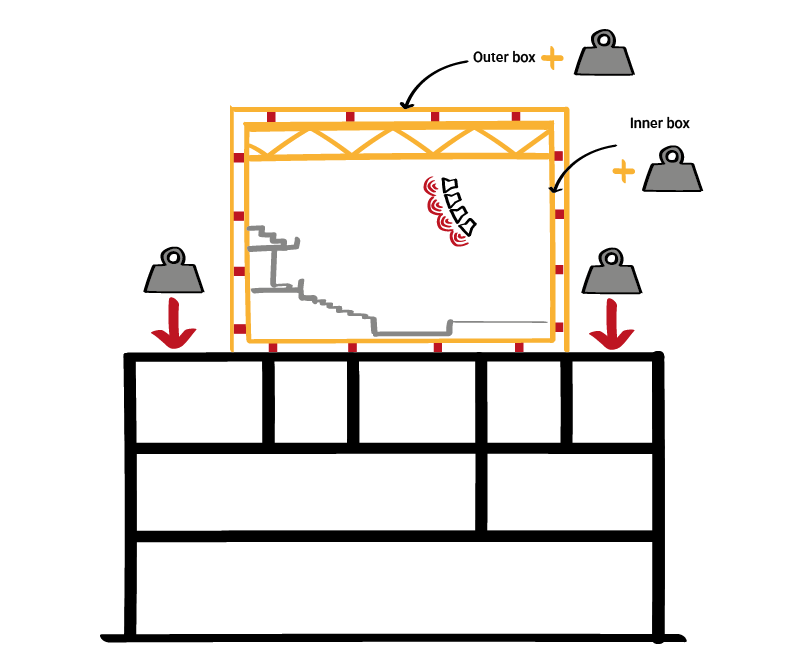

A box-in-box construction places the event space inside another box (which is structural, most of the time).

The main idea is to keep the two boxes as separate as possible to minimise the vibration transfer between them.

This separation helps contain the noise generated during events.

When you need high sound insulation, especially at low frequencies, a box-in-box system is nearly unavoidable.

It goes without saying that designing and building a box-in-box system is a complex and costly process.

Acoustic Challenge: Exposing the mass timber structure

For these types of venues, you usually want to minimise (or even avoid) the number of posts/columns for the audience and stage areas.

This leads to the need for structural elements like trusses and beams with large spans. If these elements are made of (mass) timber, it is a missed opportunity not to show them inside the venue (they do look amazing).

Implementing a box-in-box construction alongside this design can be costly and complex. In our example, it means that the visible structural elements need to be part of the inner box (most of the time) to keep the continuous disconnection between the two boxes.

The outer box would then sit on top and be supported by the inner box, like a hat.

Such a design requires careful planning from the start and continuous coordination with other disciplines, especially the structural engineers.

If you don’t need a box-in-box system, the design process will likely be much simpler.

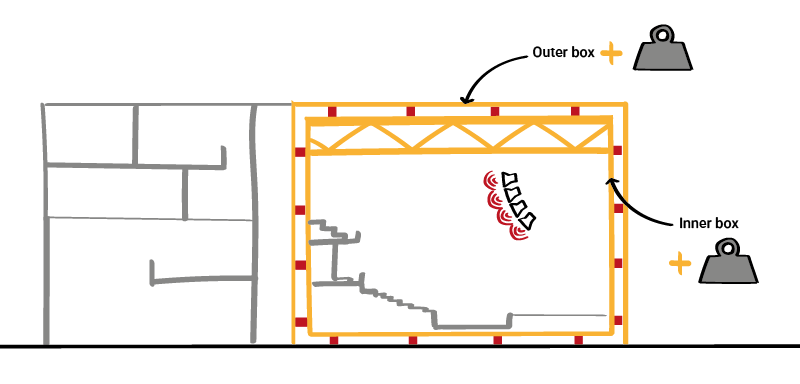

Acoustic Challenge: Adding mass

The sound insulation performance of separating elements (walls, floors, or roofs) depends on several key factors:

- the stiffness of construction elements;

- the cavities within the construction;

- the mounting conditions;

- and, crucially, the mass.

Timber is a great construction material, but it is lightweight, which poses an acoustic challenge. To improve the sound insulation in timber structures, you must add mass.

And, to insulate a timber theatre, arena, concert hall or any performance space where high levels of music are generated, it is very likely more mass will be needed.

However, adding mass typically requires denser or additional materials. These often increase construction costs and significantly raise the building’s embodied carbon.

When a new venue is planned on top of an existing building, the added mass can create structural challenges, as the original structure must be capable of supporting the additional load.

(This is yet another reason to involve the acoustic consultant early on— until the acoustic design is taken into account, it is difficult to know whether your venue project is structurally sound and financially feasible.)

Traditional materials such as concrete, plasterboard, cementitious boards and bricks effectively add mass. But producing and transporting these materials consumes a lot of energy, increasing the embodied carbon.

Thankfully, the market now offers alternative materials. These options provide the necessary mass while keeping the embodied carbon low. Examples include:

- hempcrete;

- dense sand or gravel;

- lime plaster;

- low-carbon plasterboard;

- Low-carbon concrete;

- reclaimed materials like concrete paving slabs (our current favourite!), reclaimed bricks, etc.

This list isn’t exhaustive but provides practical, sustainable options for your timber project.

Opportunity: Using Cavities and Buffer Areas for Better Sound Control

An effective way to control sound transmission—especially low frequencies—is by using:

- cavities;

- buffer zones;

- and careful planning.

By designing empty spaces or cavities within walls, floors, and roofs, you can enhance sound insulation without significantly increasing material use.

If your venue has enough space and height, you should consider increasing these cavities for better acoustic performance.

Buffer zones like corridors, circulation areas, storage rooms, or other ancillary spaces also help. Because they are less sensitive to noise, they protect quieter areas from the main event noise.

To successfully implement these strategies, you need to appoint an acoustic engineer as early as possible.

Early involvement allows proper planning of these cavities, spaces, and buffer zones, saving you time and money later.

Opportunity: Prefabricated panels and modular solutions for enhanced acoustics

If you are following the progress of modern and sustainable methods of construction, you may have noticed the rise of prefabricated panels and modular solutions with interesting acoustic performances.

In fact, many of them come with pre-installed acoustic treatment, integrating the necessary mass, sound insulation treatment, and acoustic finishes, helping control both sound transmission and reverberation once installed.

Some examples we really like are as follows.

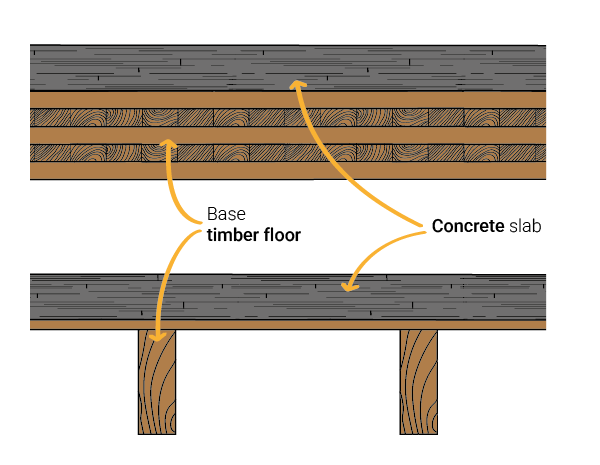

Timber Concrete Composite (TCC) systems

TCC systems pair a concrete slab with a timber base floor (CLT or glulam usually, but not always).

Though less sustainable because of the concrete, they add mass for better sound insulation, fire resistance, and stiffness (depending on how bonded is to the timber).

They could be used in areas where high sound insulation is essential.

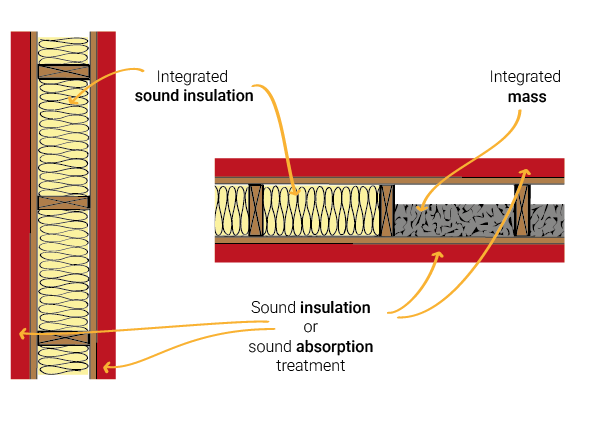

Timber cassette systems

Prefabricated timber panels for walls, floors or roofs—timber cassette systems are lightweight, fast to install and use less timber.

Acoustic treatment can be added on either sides or integrated into the cassettes to improve sound insulation and sound absorption performances.

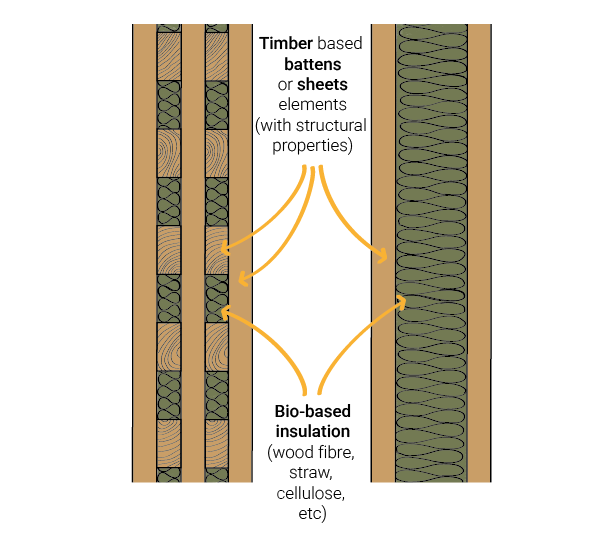

Wall timber systems

Wall systems combining structural timber elements with natural fibre insulation within the cavity.

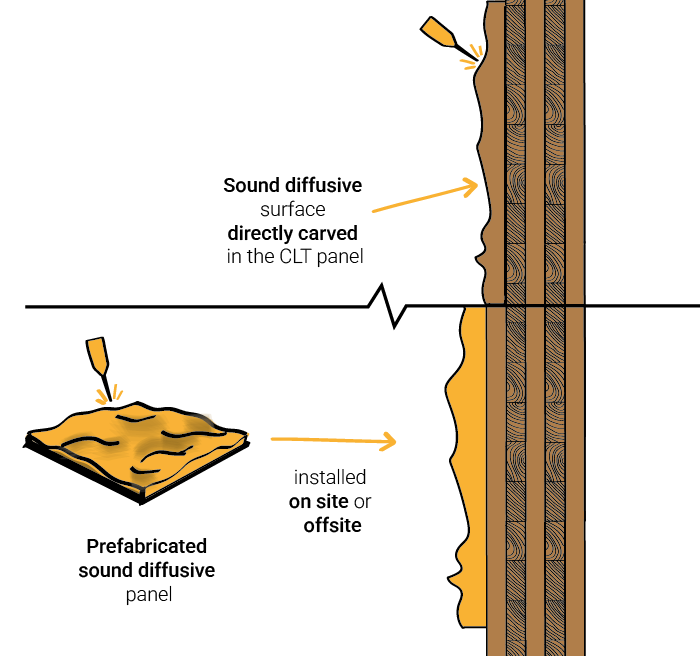

Prefabricated sound diffusive systems

Sometimes, when sound diffusion is needed, you can pre-install or even pre-carve bespoke sound diffusing surfaces (with machines or by hand) on the prefabricated panels.

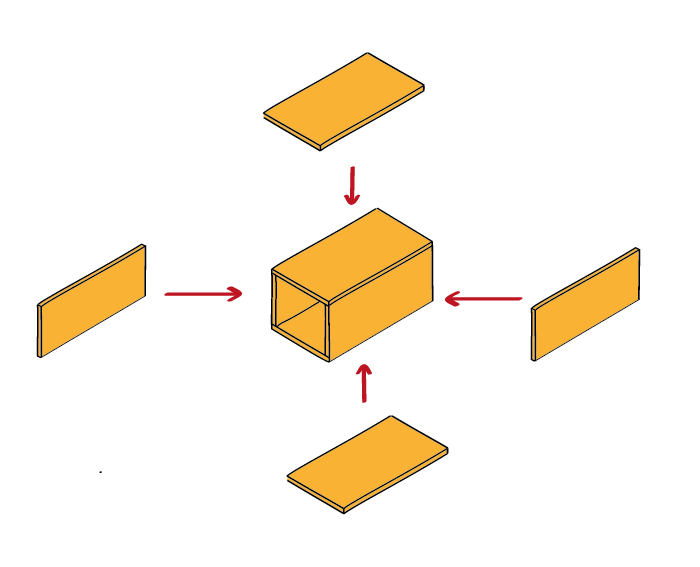

Prefabricated volumetric timber systems

Finally, prefabricated volumetric solutions could be used for spaces that don’t need wide, uninterrupted spans.

Depending on the project, choosing prefabricated solutions with these integrated acoustic features can streamline your project, saving you valuable time and potentially costs.

Involving an acoustic engineer (obviously!) and a contractor (most importantly), familiar with these systems, early in the project is key to achieve the best results.