Are you designing a building with slabs made of Cross Laminated Timber? And would you like the underside of the slabs to remain exposed? Great idea! It will look good and feel more relaxing.

But if you expose the slabs, you have no ceilings (of course!). This is likely to make the acoustic standard of the building harder and dearer to achieve.

Ceilings might not always be visually appealing, especially when you can expose a timber structure instead, but they have several acoustic design functions that can lead to important cost savings.

This post firstly presents the acoustic functions of suspended ceilings. It then summarises some design alternatives you could think about if your budget allows you to expose the CLT slabs.

Enjoy the read!

Need an Acoustic Design Audit?

You are at the beginning or concept design stage of a timber project and need a direction for the acoustic design?

Atelier Crescendo offer a bite-sized, zero-cost service including:

📞 a 30-minute call to do through the project and proposals

🪵🔍 a quick review of the timber structure

🪵 assessment of up to 3 wall build-ups

🪵 assessment of up to 3 floor build-ups

✍️ a concise 1–2-page design note to summarise our recommendations

We will do it wherever your project is.

Acoustic design functions of suspended ceilings

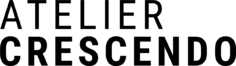

Acoustic designers can advise for the installation of suspended ceilings to control:

- the airborne sound insulation performance of floor constructions.

- the impact sound insulation performance of some floor constructions.

- the sound flanking:

- above partitions (through the slab and via the gap at the head).

- via building services and structural penetrations through partitions.

- via structural elements (like the beams) running across partitions.

- the sound reverberation within the spaces.

- the noise of building services hung from the soffits.

The sketch above pictures the above functions.

Alternative design solutions, to using suspended ceilings, exist but very few of them combine all the above functions. Each alternative has its own cost, which overall is likely to require a higher budget than when suspended ceilings are installed.

Acoustic design alternatives

You could justify a higher budget to benefit from the aesthetics of the exposed timber and other qualities like smell, healthy feeling or also absorption of humidity.

In that case, this section presents examples of solutions and materials that could help you achieve the acoustic standards you target for the building.

Note

Generally, the detailed solutions depend on the acoustic requirements, the structural design and the layout of the building. Anything shown below is just indicative.

Controlling the airborne and impact sound insulation

Controlling the airborne and impact sound insulation of a floor construction involves:

- adding more mass to the build-up.

- decoupling the flooring elements to reduce the transmission of vibrations (here, the floor finishes need to be decoupled from the slab).

Air cavities can also partially compensate for the lack of mass to increase the sound insulation performance of floor constructions.

Note

You should expect thicker toppings for timber constructions to achieve similar sound insulation performances achieved by masonry constructions. This is because the materials used in timber buildings are not as dense, so larger volumes are needed to match the mass of masonry elements.

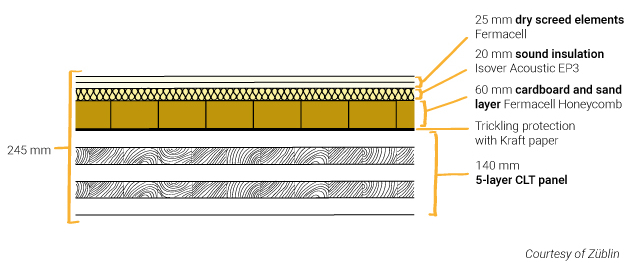

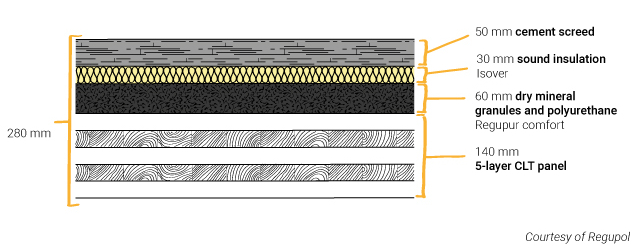

Concrete Screeds

A concrete screed isn’t the quickest and the most sustainable option, but it is an easy way to increase the mass and the stiffness of a construction with a relatively thin layer.

You usually pour concrete screeds on resilient layers to improve the impact sound insulation performance of a floor construction.

Note

In the realm of timber floors, most Timber-Concrete Composite (TCC) systems have better airborne and impact sound insulation performances at low frequencies. You can read the post Why we need to think beyond building regs for the sound insulation of CLT constructions on the need to consider low frequencies that are not imposed by the UK building regs.

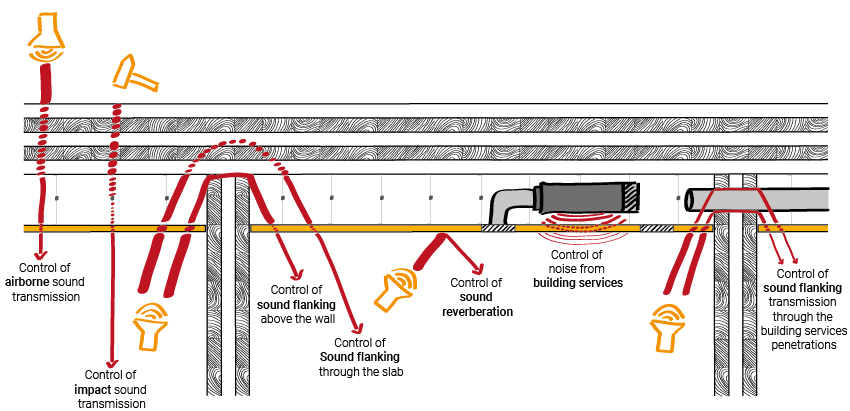

Dry Screeds

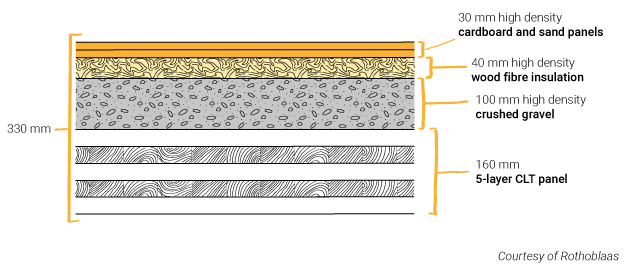

Dry screeds are not as dense as concrete screeds, but they are still a good way to increase the mass of a floor build-up. Their main advantage is that you can install them quickly without needing time to dry.

You can build dry screeds with either the same or a combination of different dense boards like plasterboard, plywood, particle boards, cementitious boards or even cardboard panels filled with sand.

They are generally laid on resilient or soft materials to increase the impact sound insulation performance of the floor constructions.

Systems with Air Cavities

As mentioned above, having an air cavity with mass on top is another way (than purely mass) to improve the sound insulation performance of a floor build-up. Systems for mass timber floors could be:

- Raised floors on resilient materials and wool/fibre boards within the air cavity;

- Thick wool or fibre quilts with mass above. To find such materials, visit the sound insulation material section of the Acoustic Design Catalogue . You can then go to categories such as glass wool, rock wool and wood fibre.

Fine sand/gravel screeds

Fine sand/gravel screeds are not used in all countries, but they are a great and simple way to improve both the airborne and the impact sound insulation performances of floor build-ups.

You can also install them quickly, you don’t need to wait for them to dry and you can level the floors with some of them.

Examples

The sketches below show some examples of combinations using the materials presented above, achieving minimum Rw 58 dB (airborne sound insulation performance) and maximum Ln,w 51dB (impact sound insulation performance).

Controlling the sound flanking above critical partitions

For any building, the acoustic designer pays important attention to the junctions between the construction elements. There is a need to control the vibrations transmitted from one element to another, up to the partitions (walls or ceilings) that re-radiate sound in the neighboring spaces.

Timber constructions are very sensitive to such transmissions. Therefore an important part of the acoustic design is to find effective methods to decouple the elements.

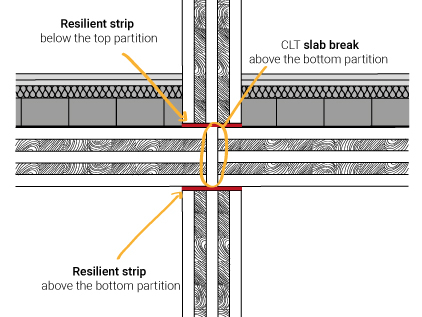

The most relevant methods depend on the structural design, the architectural design and the acoustic performances you target. Although, if you want to expose the underside of the CLT slabs, slab breaks and resilient strips are good solutions to think about from an early stage.

Slab breaks

Breaking the slabs above the partitions reduces the transmission of vibrations from one side of the partition to the other. Doing it might increase costs, but it can be very acoustically efficient in some cases.

See the figure below showing where a slab break could be.

Resilient strips (or resilient interlayers)

Resilient strips (also called resilient interlayers) are installed at the junctions of the CLT panels to control the transmission of vibrations in the rest of the structure. Most strips are made of elastomers but some use cardboard filled with sand.

When exposing the CLT slabs, you install resilient strips above the critical partitions and possibly at the bottom of the partitions resting on the slab above.

See below an example to illustrate this.

To minimise acoustic bridging, resilient strips can also be used to decouple the fixings that hold the CLT elements together.

Note

The anti-vibration characteristics of resilient strips depend on the load applied to them and how they are compressed. Therefore, the ideal specification for them will be the result of a thorough coordination between the structural designer and the acoustic designer.

Controlling the sound flanking through the building services penetrations

In the absence of a ceiling, the acoustic designer will generally advise you to not run the services (ductwork, cables, etc) through critical partitions (i.e. those acoustically rated and with an on-site requirement).

Instead, they should preferably run through the partitions that include a door. You will still need to carefully seal the penetrations to avoid any acoustic ‘leakage’. Dense mineral wool, plasterboard and non-setting mastic are examples of materials you can use for this.

Controlling the sound flanking via the structural elements

In the absence of a ceiling, you are likely to require to box in the structural elements. Although it depends on the acoustic rating of the partition the structural element is going through.

Boxing in structural elements generally involves plasterboard and mineral wool inserted in the air cavities.

Controlling the sound absorption within critical rooms

If you expose the timber slabs, you can’t rely on the ceilings to control the sound reverberation in the spaces. Instead, you will need to use sound absorptive elements and finishes that are either suspended from the soffit or fixed to the walls and the floors. These could be:

- Horizontal acoustic rafts suspended from the soffit.

- Vertical acoustic rafts also suspended from the soffit.

- Acoustic wall panels fixed on the walls.

- Carpet.

Depending on the space, you need to find a combination of all the above to achieve suitable reverberation conditions.

Controlling the noise generated by building services

If the building services (like FCUs, VAV boxes, etc) hung from the soffit are too loud and you don’t have a ceiling to attenuate the noise, the solutions would either be to insulate the casing of the units, encasing them (within bulkheads for example) or even sometimes fit new attenuators.

You could also think about reselecting the units for quieter ones.

Final thoughts

If you expose the CLT slabs, you should expect more site inspections as any loss of quality in the workmanship will have a big influence on the acoustic performance of the walls and the floors.