Often, we, acousticians, are asked about the fundamentals of sound absorption.

We are also asked to explain sound absorption data received by suppliers & manufacturers of sound absorbing materials.

If you you need clarification on sound absorption, we wrote this article for you.

It explains

- what a sound absorber is

- how we rate the sound absorption capacity of materials.

- how we measure the sound absorption coefficient of materials.

Enjoy the read!

(See at the end the references used to confirm the concepts)

Do you want to be notified when new posts are published?

Why don’t you subscribe to Atelier Crescendo’s newsletter by clicking here?

What is a sound absorber ?

A succinct definition of a sound absorptive material is:

A sound absorptive material is a material that acts as a 'noise sponge' by converting the sound energy into heat within the material.

Environmental Impact Assessment, Theory and Practice - Anji Reddy Mareddy

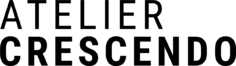

When sound strikes a material, some of its energy converts to heat, reducing the reflected sound energy.

The sound absorption of construction materials typically spans across narrow or wide frequency ranges, not single frequencies.

(if you need to understand what frequencies are read this article, and frequency bands read this article)

Various factors influence a material’s sound absorption in a space:

- the material type (hard, fibre-based, porous, etc)

- the thickness

- the finish (painted, cloth-covered, plastered, etc)

- the placement in the space

- the mounting method (on/off hard surface, free-hanging, etc)

Common sound absorptive solutions in construction use porous, fibrous, or cellular materials.

Other solutions utilize these materials with additional features like cavities, perforations or microperforations to enhance the sound absorption across specific frequency ranges.

Examples of materials will be presented in future posts.

How do we rate the sound absorption capacity of materials ?

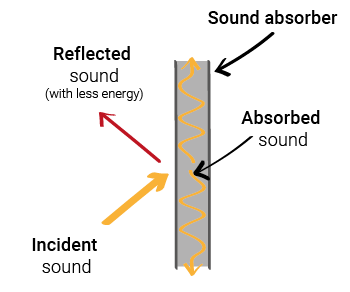

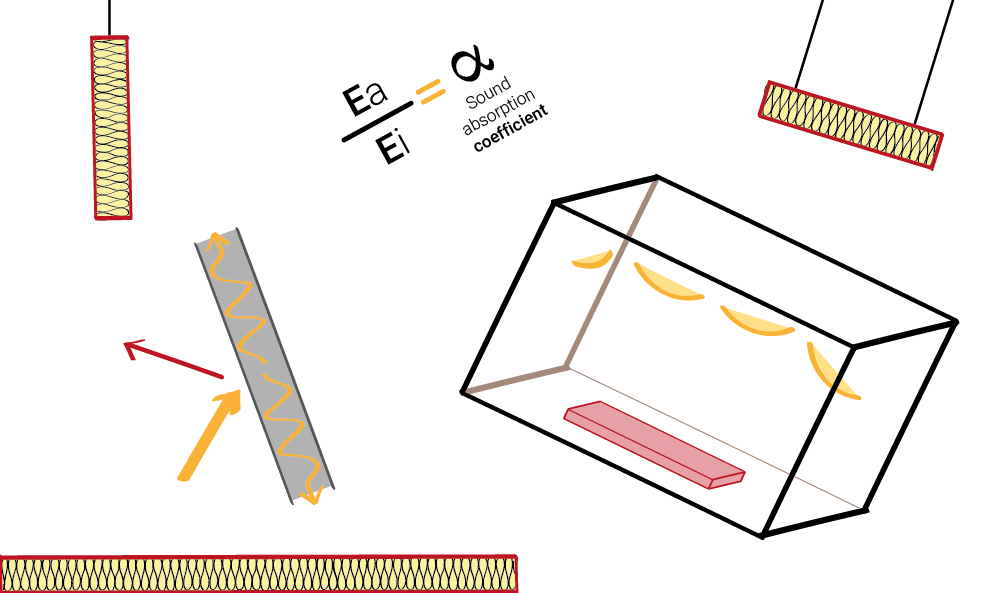

For most construction materials, a common index to rate the sound absorption is the sound absorption coefficient , termed α (‘alpha’).

Note

It is officially called the Practical Sound Absorption Coefficient, termed αp, in the standard ISO 11654 (2023) – Sound absorbers for use in buildings – Rating of sound absorption.

This coefficient is the ratio of:

- the sound energy absorbed (Ea) by a material;

- divided by the sound energy incident (Ei) on the same material.

As the absorbed sound energy (Ea) increases, the sound absorption coefficient increases too.

Conversely, a decrease in absorbed sound energy results in a lower absorption coefficient.

Thus, better sound absorption yields a higher absorption coefficient, logically.

Note

It’s worth also noting that Ea can’t physically be higher than Ei (there can’t be more absorbed energy than there is incident energy).

Hence Ea ≤ Ei always, ensuring that the sound absorption coefficient is always between 0 and 1.

However, coefficients higher than 1 may occur due to testing methods or calculations.

Other methods and indices for evaluating sound absorption of building materials include:

- the Noise Reduction Coefficient (NRC) and Sound Absorption Average (SAA) as per ASTM C423 – Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method

- the Weighted Sound Absorption Coefficient (αw) as per ISO 11654 (2023).

- the Sound absorption class (ranging from E to A, with A being the highest), as per ISO 11654 (2023)

- the Equivalent sound absorption area.

The latter two will be elaborated in future posts.

How do we measure the sound absorption coefficient of materials ?

There are two main methods to measure the sound absorption coefficient of a material:

- the Impedance Tube Method.

- the Reverberation Chamber Method or Room Method.

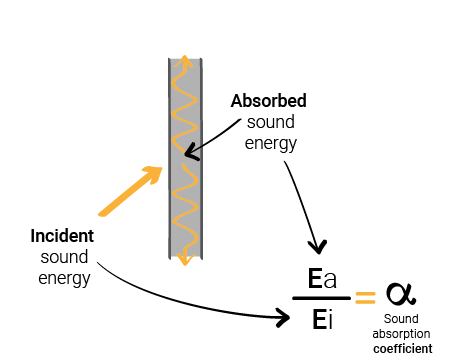

The Impedance Tube Method

This method involves placing a sample of material at the end of a small tube.

Sound is emitted into the tube at different frequencies.

The sound absorption coefficient of the material is then derived by comparing the sound in the tube before and after it strikes the sample.

While more practical and time-efficient, this method is not preferred due to its restrictions on the type of material and mounting conditions.

Note

Under the impedance tube method, there are actually two sub-methods:

the standing wave ratio method and;

the transfer function method.

Both are prescribed by normative regulations outlined in the following standards:

ISO 10534-1 (2022) – Determination of sound absorption coefficient and impedance in impedance tubes – Part 1: Method using standing wave ratio.

ISO 10534-2 (2023) – Determination of sound absorption coefficient and impedance in impedance tubes – Part 2: Transfer-function method.

ASTM E 1050-19 – Standard test method for impedance and absorption of acoustical materials using a tube, two microphones and a digital frequency analysis system.

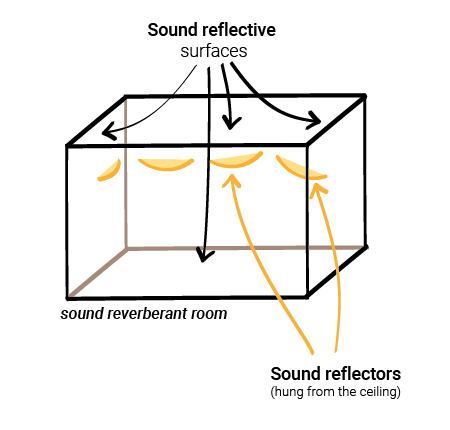

The Reverberation Chamber or Room Method

This method involves placing large samples or multiple samples of the material to be tested in a large & highly reverberant room.

The room typically comprises hard surfaces (walls, ceiling, and floor) that reflect sound, absorbing minimal to no sound, along with large sound reflective surfaces hung from the ceiling and sometimes positioned near the walls.

This setup aims to scatter sound extensively, creating a diffusive sound field within the room. This enables simulation of sound reaching the samples from all directions.

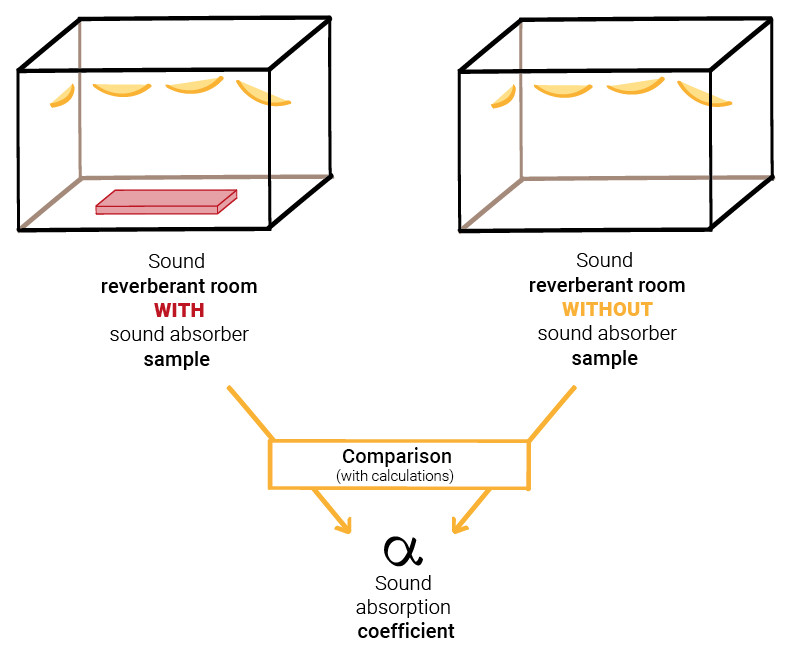

The sound absorption coefficient is calculated by comparing:

- Sound reverberation measurements without any materials.

- Sound reverberation measurements with the material under test.

Note

This measurement methodology is prescribed in EN ISO 354 (2003) – Acoustics Measurement of sound absorption in a reverberation room mention.

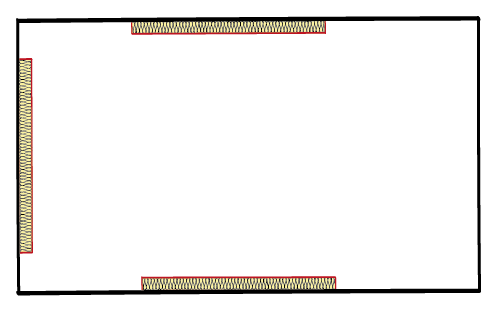

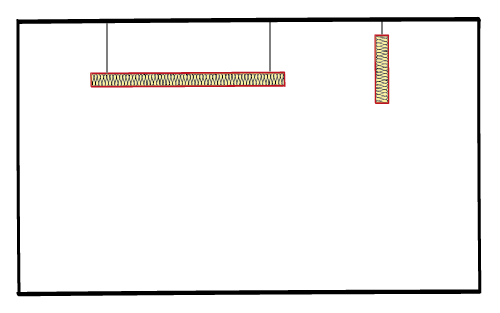

While not as practical or time-effective as the impedance tube method, this approach offers the advantage of testing materials in more realistic mounting conditions. These include (but not only):

- Mounted directly against a hard surface.

- Hung freely.

- Positioned within a cavity.

- Split into small samples.

- And many others

Note

EN ISO 354 also provides guidance (in Appendix B) on the

appropriate mounting of the test sample whether it is:

mounted directly against a surface of the reverberant room (Types A and B).

mounted with an airspace behind it (Type E)

hung parallel to a surface of the reverberant room (Type G)

spray- or trowel-applied to a substrate , usually sound absorptive (Type I)

with one edge resting on or touching a room surface (Type J)

We will provide examples of sound absorption coefficients for different construction materials in future posts.

Acoustic references

See below the references used to confirm the above concepts:

- Noise Control in Building Services – Sound Research Laboratories Ltd – Pergamon Press

- Sound Materials, A Compendium of Sound Absorbing Materials for Architecture and Design – Tyler Adams – Frame Publishers

- Acoustic Absorbers and Diffusers – Theory, Design and Application – Third Edition – Trevor Cox, Peter D’Antonio

- Engineering Noise Control – Sixth Edition – CRC Press – David A. Bies, Colin H. Hansen, Carl Q. Howard, Kristy L. Hansen

- Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites – (A volume in Woodhead Publishing Series in Composites Science and Engineering) Mohammad Jawaid, Mohamed Thariq & Naheed Saba – Woodhead Publishing – 2019