![Beyond Building Regs: Designing Timber Constructions for Better Sound Insulation Timber constructions offer many advantages as an alternative to concrete, masonry, or steel for building structures. However, designing with mass timber poses unique challenges for acousticians. Compared to masonry or concrete, timber is significantly lighter and has a relatively high stiffness—for example, in-situ concrete is roughly four times denser than typical engineered timber. Because sound insulation improves with mass, timber constructions often require additional layers—such as concrete screeds, plasterboard, dense panels, or mineral infills—to meet the acoustic performance levels required by British building regulations. But is that enough to ensure acoustic comfort? In many cases, no. Enjoy the read! (See at the end the references used to confirm the concepts) Do you want to be notified when new posts are published? Why don’t you subscribe to Atelier Crescendo’s newsletter by clicking here? Need an Acoustic Design Audit? You are at the beginning or concept design stage of a timber project and need a direction for the acoustic design? Atelier Crescendo offer a bite-sized, zero-cost service including: 📞 a 30-minute call to do through the project and proposals 🪵🔍 a quick review of the timber structure 🪵 assessment of up to 3 wall build-ups 🪵 assessment of up to 3 floor build-ups ✍️ a concise 1–2-page design note to summarise our recommendations We will do it wherever your project is. Book it here Building regulations for sound insulation were originally designed around heavy structures like concrete. These standards typically assess performance across 100 Hz to 3150 Hz, a range that overlooks the low-frequency weaknesses of timber constructions. However, timber floors and walls often underperform below 200 Hz compared to heavyweight systems. Because regulations exclude this frequency range, they fail to reflect the actual acoustic experience within timber buildings. Why Frequency Range Matters in Timber Acoustic Design To properly evaluate sound insulation in timber buildings, designers should extend the assessed frequency range to include frequencies below 100 Hz. Timber’s lighter mass allows more low-frequency energy to pass through, which standard testing doesn’t capture. By accounting for these lower frequencies, project teams can more accurately predict and improve acoustic comfort in mass timber construction. Why “Just Meeting Code” Isn’t Enough When a timber building only meets the minimum regulatory standard, occupants are likely to experience discomfort from low-frequency noise, such as: Airborne noise from hi-fi systems, musical instruments, appliances, and building services Structure-borne vibrations from footsteps, impacts, and mechanical systems Research—including the ACOUBOIS project—has highlighted this issue. Experts recommend using the L’nT,w + C50-2500 index to measure impact sound pressure levels from 50 Hz to 3150 Hz, offering a much clearer picture of how timber floor systems perform acoustically. Note ACOUBOIS was undertaken for residential buildings only and suggests more similar studies to confirm the findings. Comparing Timber and Concrete Floors: Low-Frequency Weakness Exposed Take two floor constructions—one built in timber, the other in concrete. Both include similar finishes and a suspended ceiling. Each achieves Ln,w 59 dB in the lab. However, the timber floor shows weakened sound insulation below 100 Hz, a range the building regulations ignore. The concrete floor maintains better performance across the entire spectrum. Timber constructions offer many advantages as an alternative to concrete, masonry, or steel for building structures. However, designing with mass timber poses unique challenges for acousticians. Compared to masonry or concrete, timber is significantly lighter and has a relatively high stiffness—for example, in-situ concrete is roughly four times denser than typical engineered timber. Because sound insulation improves with mass, timber constructions often require additional layers—such as concrete screeds, plasterboard, dense panels, or mineral infills—to meet the acoustic performance levels required by British building regulations. But is that enough to ensure acoustic comfort? In many cases, no. Comparing Timber and Concrete Floors: Low-Frequency Weakness Exposed Take two floor constructions—one built in timber, the other in concrete. Both include similar finishes and a suspended ceiling. Each achieves Ln,w 59 dB in the lab. However, the timber floor shows weakened sound insulation below 100 Hz, a range the building regulations ignore. The concrete floor maintains better performance across the entire spectrum. Impact sound pressure level performances of floor constructions with a Cross laminated timber base and a concrete base, both achieving Ln,w 59 dB (data courtesy of Pliteq) Figure 1 – Impact sound pressure level performances of floor constructions with a CLT base and a concrete base, both achieving Ln,w 59 dB (data courtesy of Pliteq) Note A lower Ln,w means better impact sound insulation. Designers use this lab metric to ensure floors meet on-site performance targets like L’nT,w, in line with British acoustic standards. How to Design Timber Buildings for Acoustic Comfort To enhance acoustic performance in timber constructions: Set acoustic goals early in the project Identify rooms sensitive to low-frequency noise Use design criteria that include sub-100 Hz frequencies Auralisation—which simulates different acoustic outcomes—helps teams hear the effects of their design choices and select the most appropriate solution. Where necessary, acoustic consultants will recommend ways to improve low-frequency performance, such as: Adding floating floor systems Installing resilient layers Adjusting partition layouts These strategies can significantly enhance the sound insulation of timber buildings, ensuring long-term occupant comfort. Acoustic references This post has been largely influenced by the review of the German [2] and Swedish [3] building regulations that already include airborne and impact sound insulation requirements below 100 Hz. [1] Acoubois – https://www.codifab.fr/actions-collectives/bois/acoubois-performance-acoustique-des-constructions-ossature-bois-1310 [2] DIN 4109-1 (2018) – Sound insulation in building construction – Part 1: Minimum requirements [3] Boverket’s Building Regulations (BBR)](https://ateliercrescendo.ac/wp-content/uploads/2020/08/Atelier-Crescendo-Manchester-CLT-low-frequency-sound-1-1.jpg)

Timber constructions offer many advantages as an alternative to concrete, masonry, or steel for building structures.

However, designing with mass timber poses unique challenges for acousticians.

Compared to masonry or concrete, timber is significantly lighter and has a relatively high stiffness—for example, in-situ concrete is roughly four times denser than typical engineered timber.

Because sound insulation improves with mass, timber constructions often require additional layers—such as concrete screeds, plasterboard, dense panels, or mineral infills—to meet the acoustic performance levels required by British building regulations.

But is that enough to ensure acoustic comfort?

In many cases, no.

Enjoy the read!

(See at the end the references used to confirm the concepts)

Do you want to be notified when new posts are published?

Why don’t you subscribe to Atelier Crescendo’s newsletter by clicking here?

Need an Acoustic Design Audit?

You are at the beginning or concept design stage of a timber project and need a direction for the acoustic design?

Atelier Crescendo offer a bite-sized, zero-cost service including:

📞 a 30-minute call to do through the project and proposals

🪵🔍 a quick review of the timber structure

🪵 assessment of up to 3 wall build-ups

🪵 assessment of up to 3 floor build-ups

✍️ a concise 1–2-page design note to summarise our recommendations

We will do it wherever your project is.

Building regulations for sound insulation were originally designed around heavy structures like concrete.

These standards typically assess performance across 100 Hz to 3150 Hz, a range that overlooks the low-frequency weaknesses of timber constructions.

However, timber floors and walls often underperform below 200 Hz compared to heavyweight systems.

Because regulations exclude this frequency range, they fail to reflect the actual acoustic experience within timber buildings.

Why Frequency Range Matters in Timber Acoustic Design

To properly evaluate sound insulation in timber buildings, designers should extend the assessed frequency range to include frequencies below 100 Hz.

Timber’s lighter mass allows more low-frequency energy to pass through, which standard testing doesn’t capture.

By accounting for these lower frequencies, project teams can more accurately predict and improve acoustic comfort in mass timber construction.

Why “Just Meeting Code” Isn’t Enough

When a timber building only meets the minimum regulatory standard, occupants are likely to experience discomfort from low-frequency noise, such as:

Airborne noise from hi-fi systems, musical instruments, appliances, and building services

Structure-borne vibrations from footsteps, impacts, and mechanical systems

Research—including the ACOUBOIS project—has highlighted this issue.

Experts recommend using the L’nT,w + C50-2500 index to measure impact sound pressure levels from 50 Hz to 3150 Hz, offering a much clearer picture of how timber floor systems perform acoustically.

Note

ACOUBOIS was undertaken for residential buildings only and suggests more similar studies to confirm the findings.

Comparing Timber and Concrete Floors: Low-Frequency Weakness Exposed

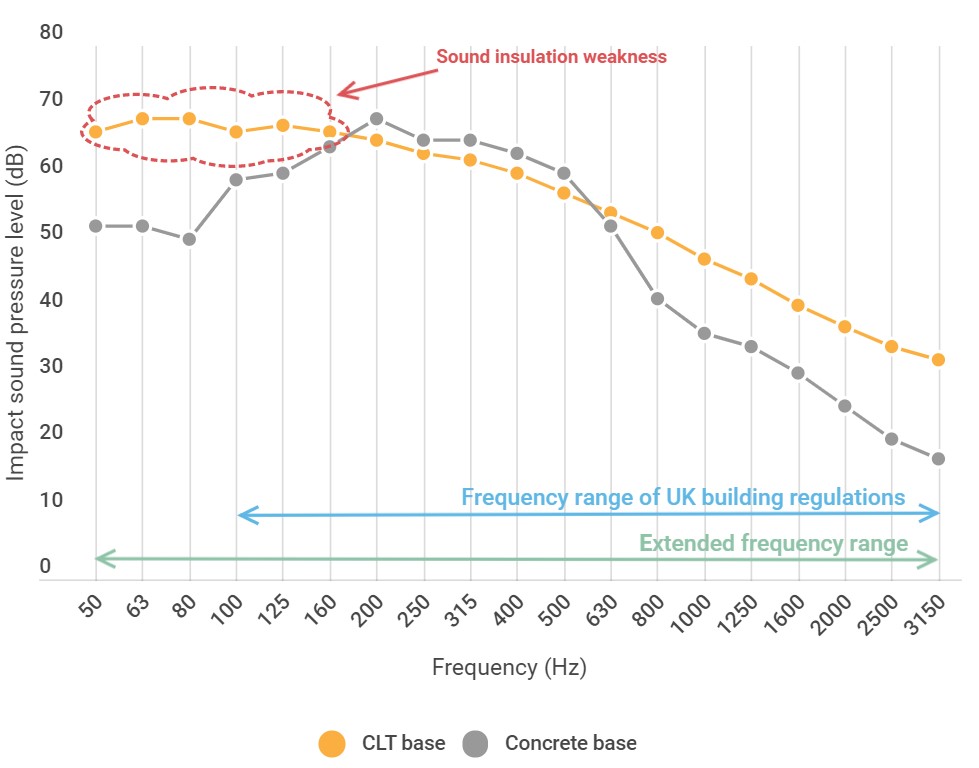

Take two floor constructions—one built in timber, the other in concrete.

Both include similar finishes and a suspended ceiling. Each achieves Ln,w 59 dB in the lab.

However, the timber floor shows weakened sound insulation below 100 Hz, a range the building regulations ignore.

The concrete floor maintains better performance across the entire spectrum.

Figure 1 – Impact sound pressure level performances of floor constructions with a CLT base and a concrete base, both achieving Ln,w 59 dB (data courtesy of Pliteq)

Note

A lower Ln,w means better impact sound insulation.

Designers use this lab metric to ensure floors meet on-site performance targets like L’nT,w, in line with British acoustic standards.

How to Design Timber Buildings for Acoustic Comfort

To enhance acoustic performance in timber constructions:

Set acoustic goals early in the project

Identify rooms sensitive to low-frequency noise

Use design criteria that include sub-100 Hz frequencies

Auralisation—which simulates different acoustic outcomes—helps teams hear the effects of their design choices and select the most appropriate solution.

Where necessary, acoustic consultants will recommend ways to improve low-frequency performance, such as:

Adding floating floor systems

Installing resilient layers

Adjusting partition layouts

These strategies can significantly enhance the sound insulation of timber buildings, ensuring long-term occupant comfort.

Acoustic references

This post has been largely influenced by the review of the German [2] and Swedish [3] building regulations that already include airborne and impact sound insulation requirements below 100 Hz.

[1] Acoubois – https://www.codifab.fr/actions-collectives/bois/acoubois-performance-acoustique-des-constructions-ossature-bois-1310

[2] DIN 4109-1 (2018) – Sound insulation in building construction – Part 1: Minimum requirements

[3] Boverket’s Building Regulations (BBR)