Mass timber constructions pose particular challenges for acoustic engineers.

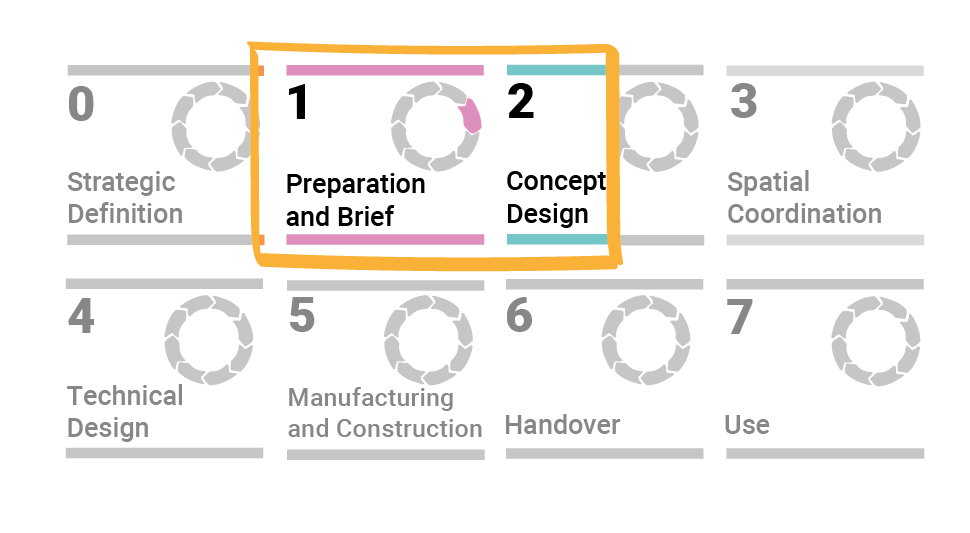

This is why the acoustic design for mass timber buildings needs to be considered earlier than on more traditional buildings. Doing this can have positive consequences on the budget, the comfort of the occupiers and the sustainability of the building.

This post gives you 8 reasons why you should follow this advice.

Enjoy the read!

(See at the end the references used to confirm the concepts)

Do you want to be notified when new posts are published?

Why don’t you subscribe to Atelier Crescendo’s newsletter by clicking here?

01

To take account of the acoustic weaknesses at low-frequencies

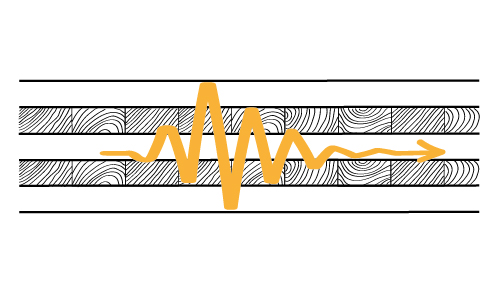

Timber constructions are known for their sound insulation weaknesses at low frequencies. This usually leads to a reduction of comfort for the occupiers.

A common problem in timber constructions is the disturbing audibility of people walking on floors.

Depending on the country, the local building regulations might not consider the right frequency range. Baring this in mind, the acoustic designer is likely to recommend the extension of the design brief for some parts of the building. For more details on this topic, check Why we need to think beyond building regs for the sound insulation of CLT constructions .

Be aware of the consequences though!

Setting these types of extensions can lead to needing more materials, implementing specific design methods and probably needing more space.

Therefore, you need to consider this as early as possible in the planning to avoid any unexpected loss of space or increase of the construction cost.

Although, there is always room for optimisation, which the acoustic designer will help you with.

Along with cavities and decoupling methods, the acoustic designer relies on adding mass to improve the sound insulation performance of the partitions.

Timber structures being very light, you really can’t avoid needing to add mass to most separations. At least, those that are acoustically rated.

Adding mass could result in a structure significantly heavier than originally planned.

Not taking onboard the need for a minimum of mass early enough in the design, could lead to surprises during the later design stages. To the point of having to re-design the structure and maybe the foundations to take account of the extra load.

02

To know how much mass is needed from the start

03

To take account of the acoustic weaknesses at low-frequencies

If not for sustainability and speed of construction, acoustic consultants would advise implementing wet solutions in timber buildings (i.e. using concrete and plaster generally).

The advantages are:

- they are made with dense materials that are very useful in adding mass to the constructions.

- because the materials are dense, you can minimise the thickness of the layers and lose less space in the buildings.

- they can increase the internal vibration damping and the stiffness of the separations.

- to a certain extent, they can fill the gaps between the timber elements.

However, dry solutions are preferred for timber buildings because the materials involved are generally less harmful to the environment, quicker to install and lighter. Three strengths mass timber constructions are very well known for.

The design techniques, materials and products to control the sound insulation with wet and dry solutions can be very different. To the point that changing from wet to dry (and vice-versa) in the middle of a design can lead to re-budgeting and sometimes re-designing.

So it is best to decide as early as possible, with the acoustic consultant, whether the design will rely on wet and/or dry construction methods.

Let’s face it: controlling the transmission of sound between spaces in timber buildings is challenging!

To comply with the design brief, the acoustic consultant will advise for more mass, more materials and more products. All of these are likely to increase construction cost.

To minimise this and stay on budget, you can work with the acoustic consultant by optimising the building layout to separate and disconnect the loud and sensitive spaces as much as possible.

This way, you will reduce the reliance of expensive measures to control the sound transmission between the spaces.

Working on the building layout can also help you minimise the embodied carbon of the building. See Reason 7.

Note

The above is not just applicable to timber buildings but to any type of building.

04

To optimise the building layout and stay on budget

05

To plan for the right amount of space

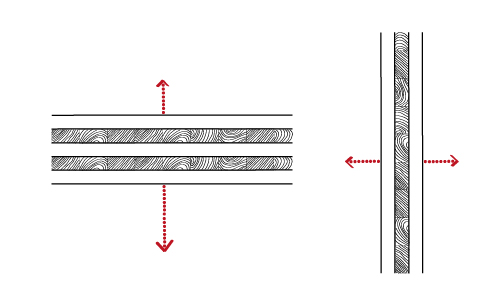

As discussed above, sound insulation design is based on associating mass, decoupling methods and cavities.

But because timber is a light material, the acoustic consultant compensates on the two latter leading separations to be generally thicker and wider.

Also, the materials used in dry solutions are not always as dense as those in used in wet solutions. So if you design your building with dry solutions and need a minimum amount of mass, it is likely that the heavy layers will need to be rather thick compared to those of wet solutions.

By knowing all the above, you can plan early for enough space between the rooms and avoid having to compromise on room size later down the line.

For mass timber projects, the acoustic design should ideally be considered at the same time as the structural design.

This is not just because more mass creates a higher load as discussed in Reason 2. It is also to work on suitable design methods to control the vibrations transmitted to/between the building elements.

Note

Vibrating elements can re-radiate audible sound. But it depends on a few different factors.

The acoustic and the structural engineers could work together on:

- the connections between the elements: depending on the fixing method, more or less vibrations are transmitted between the timber elements. The same goes with the way the elements are in contact with each other.

- cavity breaks: they can be efficient at controlling vibrations, but might not always be possible to have for structural and cost reasons.

- stiffening some separations: different methods exist to do this. You could either add more mass, connect stiffer elements with a certain degree of bonding or also reduce the spans/spacing between the structural elements.

Why is stiffening the separations important?

Because it is one way to increase their sound insulation performance at low frequencies.

06

The acoustic and structural engineers need to work together early

07

To minimise the embodied carbon and increase the sustainability of the building

Acoustic design is not very environmentally friendly.

It often relies on materials that are not sustainable or require a certain amount of energy (emitting CO2) to be produced.

In other words, acoustic design has the potential to screw up your plans for net-zero carbon!

If you start working early with the acoustic consultant, he/she can help you minimise this by working on:

- the building layout. As discussed in Reason 4, optimising the building layout is likely to reduce the use of mass, materials and products to comply with the design brief. This process can therefore have a positive impact on the embodied carbon of the building.

- implementing sustainable design methods. The main thing here is to go for dry solutions as much as possible. They use more materials and products that are sustainable and require less energy to be produced. As discussed, in Reason 3, implementing dry solutions is a choice to make as early as possible.

- using sustainable products. This choice doesn’t necessarily need to be made early in the design. Although, you might need to consider some products early as extra tests could be required. See the following paragraph for more details.

Depending on the situation, the acoustic consultant might recommend testing specific solutions because:

- They have never been tested.

- They have been tested but some performance data or details are missing.

- They have been tested, but not under the right conditions.

This is more likely to happen for timber buildings, especially when the solutions are related to sound insulation design.

It is known that, in controlling the sound insulation within timber buildings, some materials have a different efficiency on timber structures than on masonry structures.

In other words, if a material has a certain performance on a masonry construction, it doesn’t mean it will achieve the same performance on a timber construction. So you could need to re-test the material on a timber construction. (resilient layers, that help control the impact sound insulation of floor constructions, are probably the best example).

Also, a material/product might have already been tested, but the data or the testing methods are limited.

It is usually the case for the frequency range considered that doesn’t go below 100 Hz, when acoustic designers need data down to at least 50 Hz (if not 20 Hz).

For impact sound insulation testing, it is good to use a calibrated impact ball (as well as the traditional tapping machine) which is not often used to test masonry floor constructions.

Finally, we know that the sound insulation performance of mass timber elements can dramatically vary with the mounting conditions (i.e. fixings, spans and also spacing between structural elements). If the proposed mounting conditions hugely differ from those already tested, it might be necessary to undertake more tests (in a lab or on-site).

08

To plan for further acoustic testing