Acoustic plaster systems explained

Have you ever wondered what acoustic plaster systems are?

This post explains:

- What are acoustic plaster sytems?

- Advantages and uses of acoustic plaster systems

- Configurations and characteristics of acoustic plaster systems

- Sound absorption / acoustic absorption of acoustic plaster systems

- Sustainability of acoustic plaster systems

- Installation and workmanship for acoustic plaster systems

- Examples of acoustic plaster products available on the market

Note: Although acoustic plaster systems do look really good, they might not be the solution if you are on a tight budget. Some of the reasons are because they include some high-end materials and have to be installed by specialists.

Are you looking to understand how acoustic products work and find examples available on the market?

Visit the Acoustic Design Catalogue by clicking on the button below.

What are acoustic plaster systems?

Acoustic plaster systems are sound absorbing systems that are made of fibrous and porous materials to help reduce sound reverberation within spaces.

Advantages and uses of acoustic plaster systems

Acoustic plaster systems are usually installed on the ceilings, the soffits and sometimes the walls.

Their advantages are:

- they have a seamless and smooth appearance.

- they can be curved or shaped to follow a custom design.

- they can sometimes integrate heating and cooling systems.

- although white is preferred most of the time, they can be tinted or painted (with approved paint) in different colors.

Acoustic plasters are generally fire-resistant and can be made moisture resistant.

Lighting systems, sprinklers and audio systems can also be integrated.

Slide the images in the gallery below to see what acoustic pasters look like. To find examples of acoustic plaster products, visit the Acoustic Design Catalogue here.

Configurations and characteristics of acoustic plaster systems

Acoustic plaster systems usually come in pre-made panels that require final finishing on site.

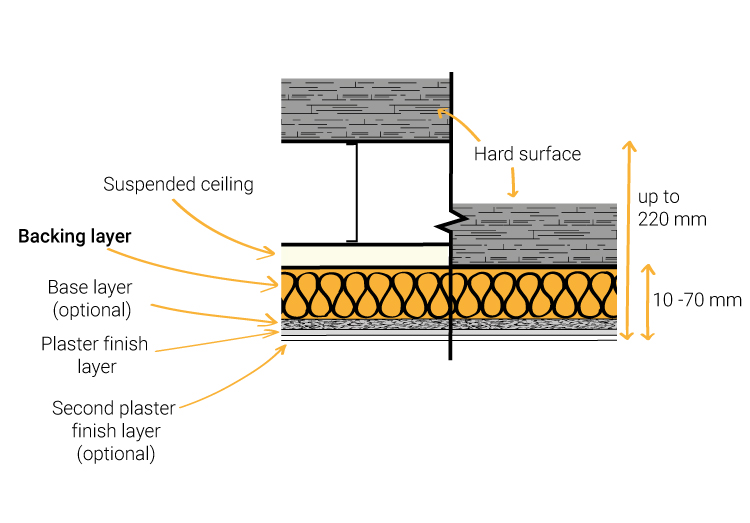

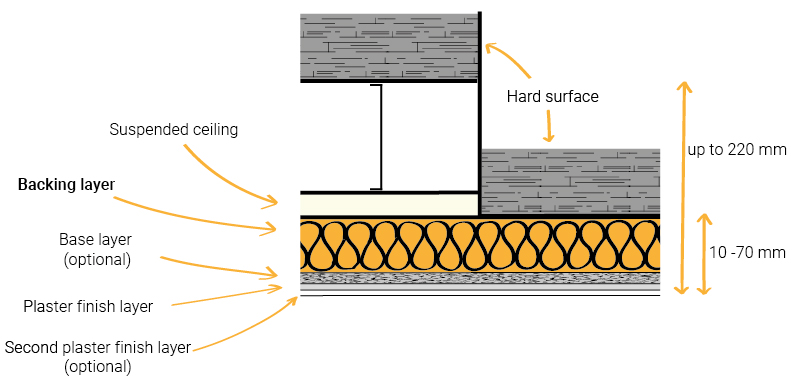

They usually include the following:

- a thick sound absorptive backing layer made of mineral wool, glass fibre, natural fibre or foam.

- a porous (acoustically transparent) and more rigid base layer.

- a thin finish layer of plaster trowel or spray applied to the backing layer.

- a second thin layer can be applied to provide a finer finish.

The thickness of the panels ranges from approximately 10mm to 70 mm.

They can either be fixed to a hard surface or as part of a suspended ceiling (in which case, the thickness of the whole system can reach approximately 220 mm).

Sound absorption / acoustic absorption of acoustic plaster systems

The sound absorption performance of acoustic plasters depends on:

- the material of the backing layer.

- the thickness of the backing layer.

- the porosity of the surface finishes.

- if fixed to a suspended ceiling, the depth of the ceiling cavity.

The sound absorption characteristics of acoustic plasters are considered for each square meter of material and can achieve a large variety of performances ranging from Class D to Class A.

Note: The sound absorption characteristics of acoustic plasters increase with the thickness of the panels, the size of the cavity behind the panels and the presence of a backing layer behind the panels.

As mentioned above, plasters can also be painted provided the paint is approved by the manufacturer. This is because paint can modify the porosity of the finish layer and change the sound absorption capacity of the system.

Sustainability of acoustic plaster systems

Some plaster systems use natural or recycled materials (such as recycled glass granulate) for the backing layer.

The plaster finish can be made from cellulose, glass or marble granular aggregate, which is a secondary material obtained from the production of natural stone.

Installation and workmanship for acoustic plaster systems

Installing acoustic plaster systems requires a high level of workmanship to obtain the sound absorption performance desired and avoid cracks appearing with time.

Suppliers either have in-house and trained installers or certified installers.

Examples of acoustic plaster products

To find examples of suitable acoustic plaster products, visit the Acoustic Design Catalogue here.