Porous sound absorbers

explained

Most (99% actually) materials used in construction to absorb sound are porous.

And do you know:

- the 3 differents types of porous absorbers?

- the importance of their porosity and air flow resistivity?

- the influence of their thickness?

- the influence of their density?

- the influence of the mounting conditions?

- the impact of the materials used to cover them?

In this post, we answer all the above questions.

Enjoy the read!

(See at the end the references used to confirm the concepts)

You want to be notified when new posts are published? Why don’t you subscribe to Atelier Crescendo’s newsletter by clicking here?

Are you looking to find examples of acoustic solutions and products available on the market?

Visit the Acoustic Design Catalogue by clicking on the button below.

What are porous sound absorbers ?

Primarily, Porous absorbers are used to diminish sound reverberation in rooms or to mitigate noise transmission when installed in cavities.

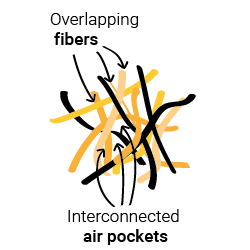

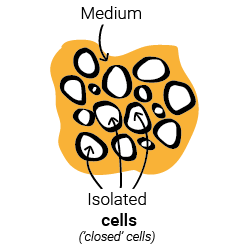

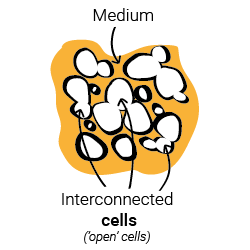

The sound absorption is achieved when sound passes through networks of interconnected pores, inducing viscous and thermal effects that dissipate acoustic energy as heat.

There are three types of porous absorbers.

Note

The shape and dimensions of the pores and fibres also significantly influence the sound absorption

Porosity and air flow resistivity of porous sound absorbers ?

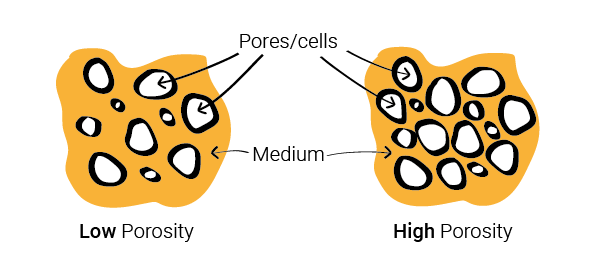

The sound absorption of a material is closely tied to its porosity and flow resistivity, representing the resistance of the air as it traverses the material.

Hence, higher porosity correlates with greater sound absorption.

Porosity is defined as the ratio of pore volume to the matrice/medium volume.

Porosity of some construction materials

Material

Typical porosities (%)

Felt

0,83 – 0,97

Hemp

0,99

Mineral wool

0,92 – 0,99

Open cell acoustic foams

(e.g. PU)

0,93 – 0,995

Rubber crumb

0,44 – 0,54

Sand

0,39 – 0,44

Marble

≈ 0,005

Influence of the thickness on the sound absorption?

When located on solid/hard surfaces, the sound absorption tends to increase with the thickness of the porous material, particularly at low and mid frequencies.

See below the sound absorption of fibreglass (53 kg/m3 density) samples of different thicknesses, fixed to a hard surface.

Sound absorption of fibreglass (53 kg/m3 density) samples of 25 mm, 50 mm, 75 mm and 100 mm thicknesses (fixed to a hard surface)

Why is that

With increasing thickness, more material exists away from the surface, where the particules’ velocity (i.e. energy) is higher than at the wall.

This leads to enhanced absorption, particularly for lower frequencies (or larger wavelengths).

If you need a refresher about frequencies and wavelengths, read this post.

Influence of the density on the sound absorption?

Similarly to the thickness, the sound absorption at low and mid frequencies typically increases with the density of a fibrous absorber.

Below are the sound absorption coefficients of mineral wool blanket samples with varying densities.

Sound absorption of mineral wool of 16 kg/m3 , 24 kg/m3, 48 kg/m3 and 60 kg/m3 densities (50 mm fixed to a hard surface)

Influence of the mounting conditions on the sound absorption?

The sound absorption of a material greatly depends on how it is mounted.

Remember the post about Sound absorption basics? We introduced ISO EN 354 (2003 – Acoustics Measurement of sound absorption in a reverberation room mention) setting measurement standards for various mounting conditions.

For instance, consider acoustic ceiling tiles, which can be either directly fixed to a soffit or suspended.

While the sound absorption is comparable at mid and high frequencies, it is notably higher at low frequencies when the ceiling tiles are suspended (see the graph below).

Sound absorption of acoustic tiles directly applied to a hard surface or suspended

Also, in Suspended acoutic rafts explained, we showed that the following aspect influence the sound absorption characteristics a raft systems:

- the sound absorption of the material installed in a room

- the size of the rafts

- the spacing between the rafts

- the distance between the rafts and the hard surface above.

Influence of the cover on the sound absorption?

In many cases, sound absorbers are covered or protected by materials such as:

- fabric

- felt

- plastic

- paint

- perforated sheet material

- slats

Some of these materials possess specific air flow resistivity and may prevent sound from passing through. Thereby reducing the sound absorption especially at the higher frequencies. Less so at low frequencies.

This is why some materials, like paint, should be avoided as they block the pores of the materials (unless it is a non-bridging paint). See below different performances for different paint applications.

Influence of paint treatment on the absorption of a sound absorber

The same applies to glue behind cloths.

Cloth, perforated sheet materials and slats are typically preferred for protecting the sound absorbers against impact and/or small particles.

References

See below the references used to confirm the above concepts:

- Noise Control in Building Services – Sound Research Laboratories Ltd – Pergamon Press

- Sound Materials, A Compendium of Sound Absorbing Materials for Architecture and Design – Tyler Adams – Frame Publishers

- Acoustic Absorbers and Diffusers – Theory, Design and Application – Third Edition – Trevor Cox, Peter D’Antonio

- Engineering Noise Control – Sixth Edition – CRC Press – David A. Bies, Colin H. Hansen, Carl Q. Howard, Kristy L. Hansen